But it sets-off an intricate dance of software, artificial intelligence, robots, vans and workers.

At an Ocado warehouse just outside Luton, I’m in the middle of such a dance.

As far as I can see, hundreds of robots whizz around a grid, fetching items for online orders. They move with dizzying speed and precision.

In the early days of online shopping, when you placed an order, humans would dash around a warehouse or a store collecting your items.

But for years now, Ocado has been using robots to collect and distribute products, bringing them to staff, who pack them into boxes for delivery.

And Ocado is not the only firm investing in such automation.

In its warehouses, Asda uses a system from Swiss automation firm Swisslog and Norway’s AutoStore. In the US, Walmart has been automating parts of its supply chain using robotics from an American company called Symbotic.

Back in Luton, Ocado has taken its automation process to a higher level.

The robots which zoom around the grid, now bring items to robotic arms, which reach out and grab what they need for the customer’s shop.

Bags of rice, boxes of tea, packets of crumpets are all grabbed by the arms using a suction cup on the end.

It might seem like a trivial addition, but training a robot to recognise an item, grab it successfully and move it, is surprisingly difficult.

At Ocado around 100 engineers have spent years training the artificial intelligence (AI) to take on that task.

James Matthews, chief executive of Ocado Technology explains the AI has to interpret the information coming from its cameras.

“What is an object? Where are the edges of that object? How would one grasp it?”

In addition the AI has to work out how to move the arm. “How do I pick that up and accelerate in a way without flinging it across the room? How do I place it in a bag?” he says.

The Luton warehouse has 44 robotic arms, which at the moment account for 15% of the products that flow through the facility, that’s about 400,000 items a week. The rest are handled by staff at picking stations.

Ocado GroupThe robotic arms are being developed to handle a wider range of stock

Ocado GroupThe robotic arms are being developed to handle a wider range of stock

The staff handle items that robots are not ready for yet, like wine bottles which are heavy and have curved surfaces, making them difficult to grasp.

But the system is ramping up. The company is developing different attachments for the robot arms that will allow them to handle a wider variety of items.

“We’re just playing it carefully and ramping slowly over time,” says Mr Matthews. “It’s a deliberate constraint on our behalf, so we continue providing good service to people, and not crushed custard creams in every order, or worse, putting stuff on the track that goes under the wheels of one of the bots and creates an incident.”

In two or three years Ocado expects the robots will account for 70% of the products.

This inevitably means fewer human staff, but the Luton warehouse still has 1,400 staff, and many of those will still be needed in the future.

“There will be some sort of curve that tends towards fewer people per building. But it’s not as clear cut as, ‘hey, look, we’re on the verge of just not needing people’. We’re a very long way from that,” Mr Matthews says.

Ocado is hoping to sell its automation technology to companies outside the grocery sector. Late last year it announced a deal with Canada’s McKesson, a large pharmaceuticals distributor.

“Think about which industries have the need to move things around efficiently inside of warehouse… it’s endless,” says Mr Matthews.

So where will the automation of warehouses end? Are we heading to human-free warehouses that can run 24 hours a day?

Not so fast, says Sarah Bolton, who specialises in commercial real estate at law firm Taylor Wessing.

“It’s almost prohibitively expensive, we’re talking hundreds of millions of pounds to fully automate a warehouse,” she points out.

“So you’re really only talking about the big tenants in the really big warehouses looking at full automation, just because you have to have that size to make it anywhere near financially viable.”

She also points that automation needs modern buildings, including floors that can stand heavy weights, large spaces without support columns, so there’s less for the robots to crash into. Reliable electricity connections are also vital.

“You’re reliant on new build, and there’s a massive undersupply of new build warehouse stock in the UK at the minute,” says Ms Bolton.

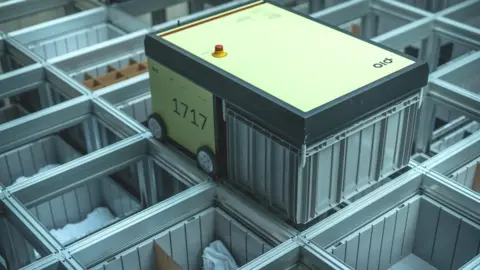

AutoStorePio offers automation systems to smaller firms

AutoStorePio offers automation systems to smaller firms

AutoStore is tackling some of those challenges. It has a company called Pio which is developing automation for smaller businesses.

It uses much of the same technology that AutoStore supplies to big firms – robots buzzing around on a storage grid where goods are stacked vertically.

However the upfront costs of Pio’s system are lower, with the cost related to the volume of goods the system handles. The software is simpler and designed to integrate easily with common e-commerce systems like Shopify.

“It’s a complete offering… where the upfront cost is very reduced. So it’s quite affordable for these companies to get access to automation and start to get the benefits out of it. And since the technology is very flexible and scalable, you can continue to basically increase volume by adding more robots rather than more storage capacity,” says Carlos Fernández, chief product officer at AutoStore.

At the moment 10 clients are running Pio’s automation system with another five customers signed up.

Mr Fernández sees huge growth potential.

“Over the coming years, there’s going to be a journey of making the technology simpler and more affordable. It won’t require you to be a large corporation to run complex automation projects, and you won’t need to invest big amounts of capital also to start getting the benefits.”

40 comments

A powerful share, I just given this onto a colleague who was doing a bit of analysis on this. And he the truth is bought me breakfast because I discovered it for him.. smile. So let me reword that: Thnx for the treat! But yeah Thnkx for spending the time to debate this, I really feel strongly about it and love studying extra on this topic. If possible, as you turn into expertise, would you thoughts updating your weblog with more particulars? It is highly helpful for me. Huge thumb up for this weblog publish!

You have observed very interesting points! ps nice site.Blog money

I went over this website and I conceive you have a lot of wonderful info , bookmarked (:.

Very interesting information!Perfect just what I was looking for! “The medium is the message.” by Marshall McLuhan.

Hey there! Do you use Twitter? I’d like to follow you if that would be okay. I’m absolutely enjoying your blog and look forward to new posts.

We stumbled over here coming from a different web page and thought I might as well check things out. I like what I see so now i’m following you. Look forward to finding out about your web page for a second time.

I view something truly interesting about your web blog so I saved to bookmarks.

Some truly nice stuff on this site, I like it.

Enjoyed reading this, very good stuff, thankyou.

Thank you for every one of your labor on this blog. My daughter loves carrying out internet research and it’s really simple to grasp why. Most people know all concerning the lively mode you create priceless strategies by means of your website and even recommend participation from other individuals on this matter so our daughter is really becoming educated a whole lot. Take advantage of the remaining portion of the new year. Your doing a powerful job.

I think you have noted some very interesting details , thanks for the post.

Great blog here! Also your web site loads up very fast! What web host are you using? Can I get your affiliate link to your host? I wish my website loaded up as quickly as yours lol

Very interesting information!Perfect just what I was searching for!

You actually make it seem so easy with your presentation but I find this matter to be actually something that I think I would never understand. It seems too complex and very broad for me. I am looking forward for your next post, I’ll try to get the hang of it!

Spot on with this write-up, I really suppose this website wants far more consideration. I’ll in all probability be again to read far more, thanks for that info.

Thanks for another informative web site. Where else could I get that type of information written in such a perfect way? I’ve a project that I’m just now working on, and I’ve been on the look out for such information.

I would like to thank you for the efforts you’ve put in writing this web site. I am hoping the same high-grade website post from you in the upcoming as well. Actually your creative writing skills has inspired me to get my own blog now. Actually the blogging is spreading its wings quickly. Your write up is a good example of it.

Great write-up, I’m normal visitor of one’s website, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

I’ve read several good stuff here. Definitely worth bookmarking for revisiting. I wonder how much effort you put to create such a excellent informative web site.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

I’ve recently started a web site, the information you offer on this web site has helped me greatly. Thanks for all of your time & work. “So full of artless jealousy is guilt, It spills itself in fearing to be spilt.” by William Shakespeare.

Its like you learn my mind! You seem to know so much about this, such as you wrote the e book in it or something. I feel that you just could do with a few percent to power the message house a bit, however instead of that, this is fantastic blog. An excellent read. I’ll certainly be back.

Great write-up, I¦m normal visitor of one¦s blog, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

Good write-up, I am regular visitor of one?¦s web site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

I have been surfing online more than three hours lately, but I by no means discovered any interesting article like yours. It’s beautiful price sufficient for me. In my opinion, if all website owners and bloggers made just right content as you probably did, the web will be much more helpful than ever before. “Perfection of moral virtue does not wholly take away the passions, but regulates them.” by Saint Thomas Aquinas.

Good write-up, I?¦m normal visitor of one?¦s website, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Hmm is anyone else experiencing problems with the pictures on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the blog. Any suggestions would be greatly appreciated.

Keep functioning ,terrific job!

I regard something really special in this website.

Thanks for your personal marvelous posting! I definitely enjoyed reading it, you happen to be a great author.I will remember to bookmark your blog and will eventually come back at some point. I want to encourage you to ultimately continue your great work, have a nice afternoon!

I really like gathering useful information , this post has got me even more info! .

Good V I should definitely pronounce, impressed with your website. I had no trouble navigating through all the tabs and related information ended up being truly simple to do to access. I recently found what I hoped for before you know it at all. Reasonably unusual. Is likely to appreciate it for those who add forums or something, website theme . a tones way for your client to communicate. Excellent task..

This design is steller! You obviously know how to keep a reader entertained. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Wonderful job. I really loved what you had to say, and more than that, how you presented it. Too cool!

Thanks for some other wonderful article. The place else may anybody get that kind of information in such an ideal approach of writing? I have a presentation next week, and I’m at the search for such info.

Very interesting points you have observed, thankyou for posting. “Jive Lady Just hang loose blood. She gonna handa your rebound on the med side.” by Airplane.

Este site é realmente fascinate. Sempre que consigo acessar eu encontro coisas incríveis Você também vai querer acessar o nosso site e descobrir mais detalhes! conteúdo único. Venha saber mais agora! 🙂

Thanks for some other great article. The place else may anyone get that type of information in such a perfect manner of writing? I have a presentation next week, and I am on the look for such information.

Some truly nice stuff on this internet site, I like it.

I am typically to blogging and i actually appreciate your content. The article has actually peaks my interest. I am going to bookmark your site and maintain checking for brand spanking new information.

Excellent post. I was checking constantly this blog and I’m impressed! Very helpful info specially the last part 🙂 I care for such info a lot. I was looking for this particular information for a long time. Thank you and best of luck.